Main Raw Material

Sugar Can Waste (Bagasse)

Sugar cane is a grass, it is a renewable resource since its consumption does not exceed its biological reconstitution. It grows back several times a year because of its rapid growth.

Bagasse is the fibrous residue from the grinding of sugar cane once the juice has been extracted. This residue is mainly composed of cellulose (vegetable fiber). Instead of being incinerated, it is therefore reused to make new products such as bio-based food packaging.

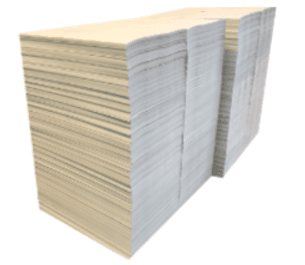

The fibres are ground to a paper pulp, dried cut into sheets of 700mmx800mmx1.3 mm usable for the production of food containers. Origin of our raw material Turkey, China, India.

Our 5-year vision is to become a brand with a strong identity, the leader of medical pulp packaging, and becoming an “impact unicorn” replacing one billion plastic products by 100% compostable products.

These leaves are kneaded in water, to disintegrate into pulp, two repellent anti-grease and water products are integrated.

Thanks to our automated machines we can thermoform any product 100% biodegradable that can be thrown into the household compost bin, or incinerated reducing by 63% the green gas emissions.

An alternative to plastic dental trays

Our GreenTech is an alternative to single-use plastic, using plant fibers such as sugar cane residues (by-product of the sugar industry) and bamboo.

Thanks to the raw material used, our products are compostable, biodegradable.

After many laboratory tests we can prove our products, even if they are incinerated for hygiene & medical reasons, reduce the green gas emissions by 63%.

Our goal is to focus on medical single use plastic products, but not only, the takeaway food industry which also generates tons of plastics waste...

Our 5-year vision is to become a brand with a strong identity, the leader of medical pulp packaging, and becoming an “impact unicorn” replacing one billion plastic product by 100% compostable products.

Our Factory

© 2026 Compack - All rights reserved